WEEK 14

Objective : To show our project and make viewers understand about the project

Activities / Procedures :

1) Finally all the hard work are paid off with flying colours.On this day, we wake up early to do a last minute review on project.

2) We arrived early at Gemilang Hall after Jumaat prayer to avoid frenzy to happen. Our assessors were switch on last minute and thankfully, the two assessors gives good comment about project and didn't hesitate to asked us on what we planned for future development.

Assessor listen to our explanation

After the event

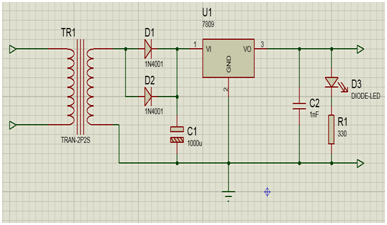

Picture of our event

3) Although we didn't win on TOP 20 fyp, but it didn't make us regret. Instead, we are more eager to make a better project if we have another chances.

Final year project have taught us many valuable experiences on how to manage time precisely and give us many knowledge to prepare us on real working place.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)